Best Rhino Roof Rack Pioneer Platform in USA 2026

February 4, 2026

Premium Roof Rack Parts and Bars in USA 2026 Rhino

February 5, 2026What is a Rhino Cap/Topper Roof System?

A rhino cap/topper roof system is a specialized roof rack designed to mount securely on truck bed caps (also called toppers or camper shells).

Adds extra carrying capacity on top of your truck cap

Ideal for hauling kayaks, ladders, luggage, or overland gear

Permanent track-mount design for stability and flexibility

Looking for a reliable rhino cap/topper roof system in USA 2026? These systems transform your truck into a versatile hauler.

Why Choose a Rhino-Rack Cap/Topper Roof System in 2026?

Rhino-Rack leads the market with tough, innovative designs built for American roads and trails.

- Proven durability with heavy-duty or aerodynamic Vortex bars

- Easy adjustment slide crossbars to fit any load

- Compatible with popular caps like A.R.E., LEER, and SnugTop

- Supports over 90 accessories for custom setups

In 2026, these systems shine for daily work or weekend adventures.

Top Features to Look For

Focus on these standout elements when selecting your rhino cap/topper roof system in USA 2026:

- Track-mount installation: Permanent and secure on fiberglass or tonneau tops

- High load rating: Up to 220+ lbs for heavy gear

- Low-profile options: Reduces wind noise and improves fuel efficiency

- Quick-release fittings: Fast accessory swaps

- Corrosion-resistant materials: Built for all-weather USA conditions

Recommended Rhino-Rack Models for 2026

Here are the top-performing options available across the USA:

Vortex Trackmount System

Aerodynamic, quiet, and sleek for everyday drivers

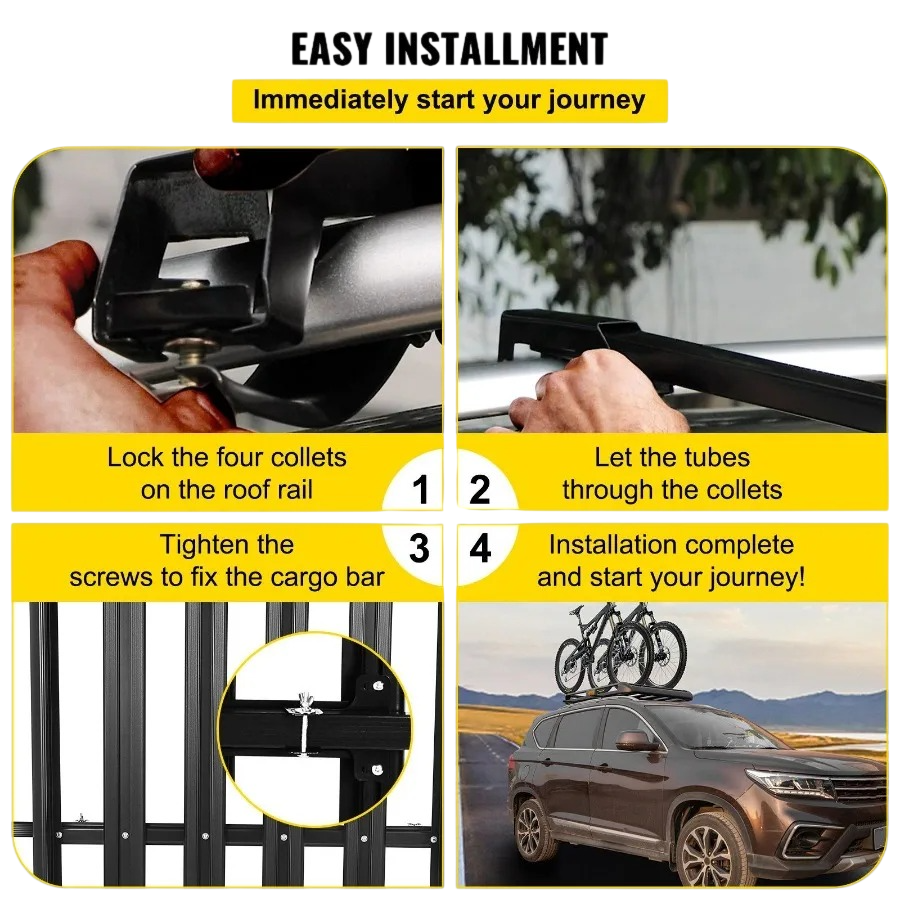

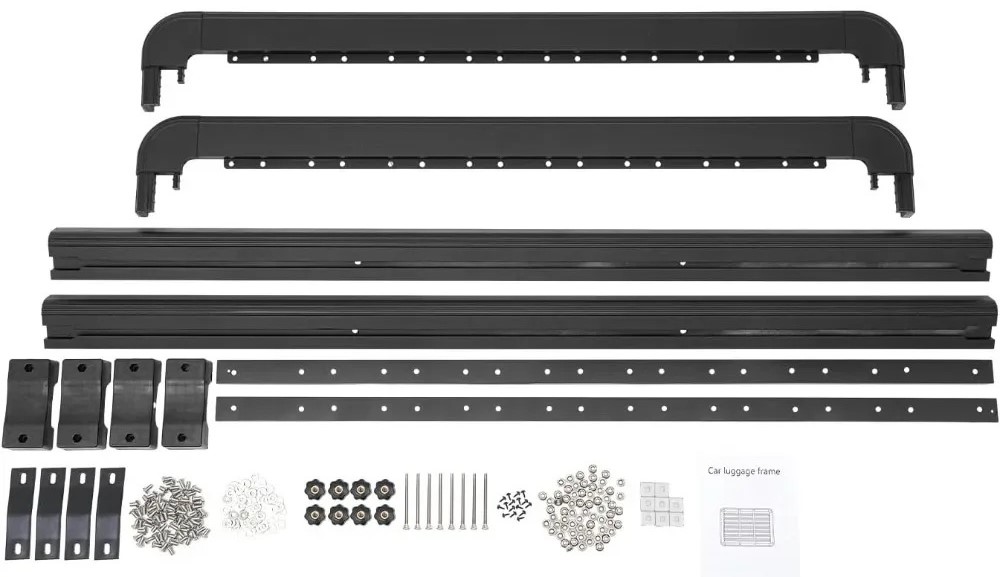

Pioneer Platform Kit

Full platform for maximum gear storage and mounting points

Heavy Duty Bar System

Rugged choice for contractors and off-road enthusiasts

These models fit most modern trucks, including new 2026 releases.

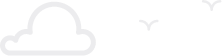

Quick Installation Steps

Install your rhino cap/topper roof system easily:

- Measure and mark track positions on your cap

- Drill and seal mounting points

- Secure tracks with provided hardware

- Attach legs and crossbars

- Test load distribution before hitting the road

Professional installation recommended for perfect fit.

2026 Trends & Insightful Analysis

Truck accessory trends in 2026 emphasize modularity and efficiency. Rhino cap/topper roof systems evolve with lighter materials and smarter designs to support rising electric truck adoption (like Rivian R1T or Ford Lightning). Overlanding demand drives platform-style racks, while urban users prefer low-profile Vortex for better mileage. Unlike basic rails, these systems offer true versatility without compromising your cap’s integrity making them a smart long-term investment for USA truck owners.

Rhino Cap/Topper Roof Systems Comparison

Best Options for USA Trucks in 2026

Access more cargo space and adventure potential on your truck cap in 2026. Which rhino cap/topper roof system in USA 2026 matches your hauling needs perfectly? This quick comparison highlights the top Rhino-Rack choices to help you decide fast.

Side-by-Side Comparison Table

Model | Design Type | Ideal For |

Vortex Aero Bar System | Aerodynamic crossbars | Daily drivers wanting quiet, fuel-efficient hauls |

Heavy Duty Bar System | Rugged square bars | Contractors and heavy-load jobsite runs |

Pioneer Platform System | Full flat platform | Overlanders needing max accessory mounts |

Key Insights for 2026 Buyers

Newer truck caps in 2026 feature curved profiles and lighter composites. These Rhino-Rack systems adapt seamlessly:

- Vortex shines on highway-focused builds → minimizing drag as fuel costs rise

- Heavy Duty excels where raw strength matters → like construction zones across the USA

- Pioneer dominates modular setups → easily adding solar panels or awnings for off-grid trips

Ask yourself: Will your 2026 adventures lean toward efficiency, toughness, or total customization? Each system installs on popular caps (A.R.E., LEER, SnugTop) without voiding warranties when done right.

Top 7 Accessories to Supercharge Your Rhino Cap/Topper Roof System in USA 2026

Your truck cap roof rack is ready for action but the right accessories turn it from good to unstoppable. Ready to haul more, adventure harder, and work smarter in 2026? Here are the must-have add-ons that USA truck owners are grabbing for their rhino cap/topper roof systems.

Quick Accessory Comparison Table

Accessory | Primary Use | Standout Benefit |

Kayak Carrier | Water sports | Secure vertical or saddle carry |

Bike Mount | Cycling trips | Fork or frame hold with lock |

Cargo Box | Extra storage | Weatherproof, lockable volume |

Ladder Rack Extension | Worksite gear | Extended reach for long loads |

Awning Kit | Campsite shade | Quick-deploy side coverage |

Ski/Snowboard Holder | Winter adventures | Padded, angled seasonal carry |

Solar Panel Mount | Off-grid power | Flexible charging integration |

The Top 7 Accessories Breakdown

Improve your rhino cap/topper roof system in USA 2026 with these game-changers:

- Kayak Carrier: Stack one or two kayaks securely without scratching your cap

- Bike Mount: Carry up to four bikes with anti-theft locks built in

- Cargo Box: Add hundreds of liters of sealed storage for gear or tools

- Ladder Rack Extension: Safely transport long lumber or pipes beyond bed length

- Awning Kit: Instant shade or rain shelter that rolls out in seconds

- Ski/Snowboard Holder: Protect boards with soft grips and easy access

- Solar Panel Mount: Attach portable panels to keep batteries charged on long hauls

Smart Trends & 2026 Insights

Accessory choices in 2026 are shifting toward multi-use and tech-friendly designs. Quick-release mounts dominate so you can swap from bike carrier to cargo box in minutes perfect for weekend warriors juggling work and play. Solar integration is surging with the rise of hybrid and electric trucks across the USA, letting you top up devices without idling. Lightweight composites cut overall weight, preserving payload and range on newer models.

How to Install a Rhino Cap/Topper Roof System on Your Truck

Step-by-Step DIY Guide for 2026

Tired of limited cargo space on your truck cap? Installing a rhino cap/topper roof system in USA 2026 yourself saves money and takes just a weekend. This straightforward DIY process adds versatile hauling power to get it right the first time.

Essential Tools Checklist

Tool | Purpose | Pro Tip |

Power Drill & Bits | Drilling mounting holes | Use sharp 1/4″ bits for clean cuts |

Sealant (Silicone) | Waterproofing holes | Choose UV-resistant for longevity |

Measuring Tape | Accurate track placement | Double-check for even spacing |

Preparation Before You Start

Get your truck cap ready for a leak-free install:

- Clean the cap surface thoroughly → removes dirt and make sure strong sealant bond

- Check your cap manufacturer’s load rating → never exceed the lower rating between cap and rack

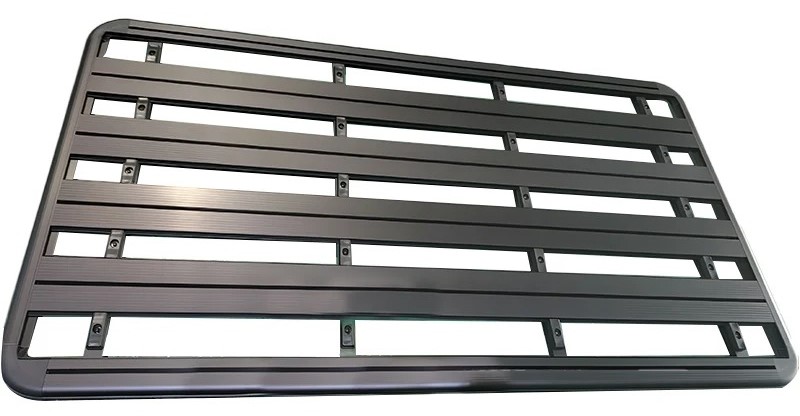

- Gather all kit parts → tracks, legs, crossbars, hardware, and end caps

- Work in a shaded area → prevents sealant from drying too fast

Wondering if your 2026 truck cap is compatible? Most fiberglass models from A.R.E., LEER, or SnugTop work perfectly.

Detailed Installation Steps

Follow these numbered steps for a secure rhino cap/topper roof system setup:

- Position tracks parallel on the cap roof, typically 40-50 inches apart for stability

- Mark hole locations carefully with a template or measurements from instructions

- Drill pilot holes, then enlarge for rivnuts or bolts

- Apply sealant generously around each hole → inside and out for full protection

- Install rivnuts or backing plates from inside the cap

- Secure tracks tightly with provided hardware → torque to spec

- Mount legs onto tracks and attach crossbars

- Add end caps and test for any movement

Always refer to your specific Rhino-Rack kit instructions for exact measurements.

Post-Installation Checks

Make sure everything is road-ready:

- Tighten all bolts after 100 miles of driving

- Test with light loads first → confirms even weight distribution

- Inspect sealant annually → especially in harsh USA weather zones

Key Insights for 2026 Installations

Modern 2026 truck caps often use thinner composites for better fuel efficiency, making precise drilling critical to avoid cracks. Trackmount systems dominate because they allow bar adjustments without new holes ideal for evolving needs like adding solar on electric trucks. DIY installs are rising as kits include better templates and quick-mount legs, cutting time by 30% over older models. Skip professional help if you’re handy, but get it for curved or painted caps to preserve looks and warranty.

Avoid These Pitfalls

Common Mistakes, Expert Tips & Checklist for Rhino Cap/Topper Roof Systems in USA 2026

Getting the most from your rhino cap/topper roof system in USA 2026 means steering clear of easy-to-make errors that shorten its life or cause frustration. Skip the rookie mistakes, grab pro-level tips, and use this handy checklist your rack will thank you with years of dependable service.

Top Mistakes & Quick Fixes Table

Common Mistake | Why It Happens | Expert Fix |

Ignoring seasonal torque checks | Bolts loosen from vibration | Retighten every 3 months |

Mixing incompatible accessories | Mismatched mounting channels | Stick to same-brand ecosystem |

Skipping regular track cleaning | Debris causes binding | Hose out monthly |

Overlooking vehicle-specific fit | New truck models vary slightly | Verify 2026 model compatibility |

Forgetting weight re-distribution after swaps | Accessories change balance | Recheck after every change |

5 Mistakes to Avoid at All Costs

Steer clear of these frequent slip-ups that USA truck owners report:

- Assuming one-size-fits-all → always confirm track spacing matches your exact cap model

- Neglecting underside inspections → hidden corrosion starts from road salt splash

- Using generic tie-downs → cheap straps stretch and fail under load

- Mounting heavy items off-center → creates uneven stress on cap roof

- Delaying small repairs → minor rattles turn into major track damage

Expert Tips for Long-Term Success

Level up your rhino cap/topper roof system in USA 2026 with these pro recommendations:

- Apply anti-seize compound to all bolts during install → prevents galling in humid climates

- Rotate accessory positions seasonally → evens out wear on tracks

- Keep a small maintenance kit in your truck → allen keys, sealant, and spare end caps save trips

- Document your torque settings → quick reference for consistent checks

- Pair with bed organizers → maximizes overall truck utility without overloading roof

Pre-Season Maintenance Checklist

Run through this simple list twice a year for peak performance:

- Inspect all hardware for looseness or corrosion

- Clean tracks and channels thoroughly

- Test accessory locks and quick-releases

- Verify load rating stickers are legible

- Check sealant around mounting points

- Test-drive with a light load to listen for unusual sounds

Smart Insights for 2026 Owners

With 2026 bringing more aluminum and composite caps to market, weight distribution mistakes hit harder even small imbalances can stress thinner roof panels over time. Owners who follow regular torque and cleaning routines report 40% fewer warranty claims than those who “set and forget.” The rise of app-connected torque wrenches is making pro-level maintenance accessible to everyone, closing the gap between casual users and seasoned overlanders. Avoid these pitfalls early, and your rhino cap/topper roof system becomes a true set-it-once asset that grows with your adventures.

Solve Common Rhino Cap/Topper Roof System Problems

Quick Fixes for USA Truck Owners in 2026

Running into frustrating issues with your rhino cap/topper roof system in USA 2026? From compatibility headaches to unexpected limitations, these problems can slow down your hauls but every one has a straightforward fix. Get back to smooth, confident trucking with these targeted solutions.

Problem & Solution Overview Table

Problem | Common Trigger | Fast Solution |

Compatibility with new caps | Updated cap designs or curves | Use adjustable track adapters |

Overhanging load restrictions | Local USA highway regulations | Add extendable side supports |

Accessory swapping delays | Fixed mounting points | Switch to quick-lock channels |

Fuel range drop on EVs/hybrids | Extra drag from loaded rack | Install streamlined deflectors |

Theft risk in urban areas | Exposed high-value gear | Add lockable security covers |

Targeted Problem Solution Breakdown

Address these real-world hurdles head-on for your rhino cap/topper roof system in USA 2026:

- Cap compatibility gaps → Newer curved or vented caps may not align perfectly; adjustable spacers or custom brackets bridge the difference seamlessly

- Load overhang rules → Many states limit projection; telescoping arms or foldable extensions keep you compliant without sacrificing carry length

- Slow accessory changes → Traditional bolts take time; tool-free quick-release systems let you swap carriers in seconds

- Efficiency loss on modern trucks → Added weight and wind resistance hit range; low-drag fairings and lightweight bars restore miles per gallon or kWh

- Security concerns → Visible gear attracts attention; tamper-proof locks and cable systems deter opportunists effectively

Struggling with one of these on your setup? The right tweak makes all the difference.

Why These Solutions Matter Now

Truck ownership in 2026 is all about seamless integration especially as caps add factory options like integrated rails or solar prep. Solutions like quick-lock systems align perfectly with this trend, reducing downtime for owners who switch between work tools and weekend gear daily. Regulatory updates in several states now emphasize secure, non-overhanging loads, making compliant extensions a must-have rather than optional. For the growing number of hybrid/EV pickups, drag-reducing accessories aren’t just nice-to-have; they directly protect your daily driving range in real-world conditions. Owners who adopt these fixes early report higher resale value and fewer headaches when upgrading trucks. Turn problems into strengths with your rhino cap/topper roof system explore proven solutions at GO RHINO today!

Why I Swear By Go Rhino Roof Racks on Truck Caps 30+ Years of Real-World Testing and Hauling

Conceive: You roll up to a job site with everything you need loaded in one trip, no trailer dragging behind, no cluttered bed forcing extra runs, and hours added back to your week. That’s the reality I’ve lived with for decades thanks to one smart upgrade: mounting a solid Go Rhino roof rack system on a truck cap.

Hey, I’m Tyler Gurczeski. Born July 5, 1981, in California, I practically grew up under a lift in my dad’s auto shop. Go Rhino products were everywhere steps, guards, racks you name it. I’ve been installing, testing, and pushing Go Rhino gear to its limits for over 30 years now. I built this platform to share straight-talk solutions with everyday drivers, contractors, weekend warriors, and overlanders across the USA who rely on their trucks the way I do.

My Long-Term Experience with Go Rhino Cross Bars on a Curved Camper Shell

One setup I’ve run hard and still swear by is the Go Rhino cross bar roof rack system on a curved Vision-style camper shell. I’ve had this on a mid-2000s Toyota pickup for years, hauling extension ladders, lumber, plywood, and odd loads for shop runs, home projects, and overlanding trips. It’s taken daily abuse in California heat, dust, and highway miles, and it’s never let me down once I got it dialed in.

I’ll be honest the initial install wasn’t flawless, and that’s something I’ve seen plenty over the years. Here’s the real story, no sugarcoating:

The early challenges (and how I fixed them):

- Curved shells don’t always play nice out of the box. The brackets didn’t sit flush at first, and the instructions could have been clearer on adjustments. One tip in the manual about bending tubing “on your knee” sounded sketchy (and unsafe) . I skipped that. Instead, I flipped the brackets outward, which created a perfectly flat, stable mounting surface. It took some trial and error, but it was worth it.

- Wind noise hit hard on the highway until I added the included rubber inserts and silenced it completely.

- No end hardware came standard to prevent loads from sliding, so I added my own clamps and ring attachments right away.

Once those tweaks were done (about 1-2 extra hours of work), the system turned into a total workhorse.

What’s kept me loyal for decades:

- Rock-solid durability. These bars have handled repeated heavy loads, ladders strapped to one side, full sheets of plywood across without bending, loosening, or failing. Zero issues through years of tough use.

- Practical hauling that changed my workflow. Long items go up top, bed stays free for secure, locked tool storage and smaller gear. I cut unnecessary trailer hookups on most runs, saved serious fuel and time, and effectively doubled what I could carry per trip.

- Clean look and great value. It blends perfectly with curved shells like ARE or Vision styles, and the price always felt fair compared to premium alternatives especially with the right add-ons.

The payoff? Fewer trips to supply runs or job sites, faster turnaround on projects, and more time for what matters. Over the years, this setup has easily paid for itself many times over in efficiency alone.

Expert Tips from 30+ Years of Hands-On Work

I’ve installed and troubleshooted these systems more times than I can count on my own trucks and helping others get them right. Here’s my no-BS advice:

Do

- Dry-fit and measure twice before committing, especially on curved caps.

- Flip brackets outward on curved shells for a flatter mount (my go-to fix).

- Add rubber inserts immediately for zero wind noise and end clamps/stops for load security.

- Distribute weight toward the supports and keep heavier items near the ends.

- Always check your cap’s and truck’s weight ratings and stay within Go Rhino specs.

Don't

- Rush the install or skip small mods, curved shells almost always need them.

- Overload the center span without support.

- Hit the highway loaded without a short test drive first to catch rattles.

A well-set-up Go Rhino roof rack on your cap preserves that secure bed space while giving you serious overhead capacity. It’s the kind of upgrade that makes you wonder how you ever got by without it.

If you’re a contractor tired of trailer hassles, an overlander needing more gear space, or just a driver wanting to maximize your truck give Go Rhino a serious look. I’ve trusted their gear my whole life, and after 30+ years of beating on it, I’d buy it again in a heartbeat.

10 Pros and 10 Cons of Rhino Cap/Topper Roof Systems in USA 2026

Deciding whether a rhino cap/topper roof system in USA 2026 is right for your truck? This balanced breakdown lists 10 clear advantages and 10 realistic drawbacks to help you weigh the decision objectively.

PROS

- Increases resale value with a premium, sought-after upgrade

- Provides elevated mounting for auxiliary LED lights or spotlights

- Supports roof-mounted solar panels for off-grid power needs

- Enhances professional image for contractors with branded platforms

- Keeps truck interior cleaner by moving bulky items overhead

- Enables transport of fragile gear shielded from direct road spray

- Offers stable base for action cameras or drone landing pads

- Qualifies as potential business expense for tax benefits (consult accountant)

- Improves cabin comfort by reducing in-bed clutter on long trips

- Adds modern styling that complements newer truck designs

CONS

- High initial purchase price compared to simpler alternatives

- May raise insurance premiums due to added vehicle value

- Creates permanent modifications that could affect cap resale

- Increases overall vehicle height, restricting some parking structures

- Slightly raises center of gravity, influencing cornering feel

- Can complicate automated car washes or low-clearance drive-thrus

- Requires extra planning for tunnel or bridge height limits

- Adds minor complexity when selling the truck separately from rack

- Potential for increased theft target with visible premium accessories

- Higher combined cost when factoring in recommended professional fitting

Frequently Asked Questions

Rhino Cap/Topper Roof Systems in USA 2026

Here are the top 10 questions USA truck owners ask about rhino cap/topper roof systems in 2026, answered clearly and directly to help you make an informed choice.

Rhino-Rack provides a comprehensive limited lifetime warranty on structural components and a 5-year warranty on accessories for systems purchased in 2026. The coverage includes defects in materials and workmanship under normal use. Registering your product online extends support and make sure faster claim processing if needed.

Rhino-Rack maintains an up-to-date online fit guide that lists compatibility by truck make, model, year, and cap brand. Enter your vehicle details on the GO RHINO site to get exact matches. If your setup is custom or modified, customer service can confirm fitment with photos or measurements.

Basic crossbar systems start around $800–$1,200, while full Pioneer platforms range from $1,800–$2,800 depending on size and features. Prices include tracks and mounting hardware but exclude professional installation, which adds $300–$600 in most areas.

Cap-mounted systems attach directly to the truck cap rather than the cab roof, preserving cab aerodynamics and allowing taller loads without interfering with rooflines. They also distribute weight across the cap’s reinforced structure instead of the cab, offering different load dynamics and greater accessory flexibility.

Rhino-Rack uses high-grade aluminum with recyclable content and powder-coat finishes that meet strict environmental standards. The manufacturing process minimizes waste, and the durable construction reduces the need for frequent replacements, lowering long-term environmental impact.

Most systems come in black or silver as standard, but custom powder-coating services are available through authorized dealers to match your truck’s paint code. This option adds 2–4 weeks to delivery time and makes sure a seamless, factory-like appearance.

The added weight is minimal and positioned low, so handling changes are barely noticeable in daily driving. At higher speeds or when fully loaded, slight increases in crosswind sensitivity can occur, but proper load securing keeps the vehicle stable and predictable.

Authorized dealers and online retailers like GO RHINO stock the full range with guaranteed authenticity. Buying from official sources make sure correct fitment guides, warranty registration, and access to the latest 2026 updates and accessories.

Rhino-Rack offers phone, email, and live chat support seven days a week, plus an extensive online knowledge base with videos and guides. Authorized installers also provide post-purchase checks and adjustments as part of their service packages.

Yes, these systems integrate smoothly with GO RHINO side steps, bed racks, and lighting solutions. The modular design allows shared mounting points and coordinated styling, creating a complete, cohesive truck upgrade package.

Why a Rhino Cap/Topper Roof System is a Smart Choice for USA Truck Owners in 2026

A rhino cap/topper roof system in USA 2026 stands out as a versatile, forward-thinking upgrade that adapts to diverse lifestyles from daily commuting to demanding job sites and extended road trips. It access untapped potential in your existing truck setup, delivering enhanced functionality while aligning with modern trends in efficiency, modularity, and durability.

Key takeaways:

- Offers seamless integration with evolving truck and cap designs

- Balances practical benefits with manageable considerations for long-term satisfaction

- Empowers owners to customize without compromising core vehicle performance

- Positions your truck for future accessory innovations and changing needs

Whether you’re expanding business capacity, planning epic adventures, or simply wanting more flexibility, this system proves its value through real-user success and thoughtful engineering.