What Does JK Mean for a Go Rhino Jeep in USA 2026?

January 18, 2026

Use Go Rhino Ratchet Straps in the USA 2026

January 20, 2026Are you struggling to release your Go Rhino ratchet strap after securing a heavy load?

Whether you're hauling gear on your truck bed, trailer, or roof rack in the USA, knowing the correct release method prevents damage to your straps, vehicle, or cargo. In 2026, Go Rhino accessories remain popular for durability. Here's your quick, safe guide.

Why Proper Release Matters for Your Go Rhino Ratchet Strap

Releasing tension the wrong way can jam the mechanism or cause sudden snap-back. Follow these steps for smooth, injury-free unloading every time.

Step-by-Step: How to Release a Standard Go Rhino Ratchet Strap

Most classic ratchet tie-down straps (including many Go Rhino compatible styles) use this reliable method:

Pull up on the release lever

Lift it fully while pushing the handle forward and down (or flat open).

Remove hooks

Unhook both ends carefully once slack.

Pro Tip: If it’s stuck (common after heavy use), wiggle the handle slightly while holding the release and never force it!

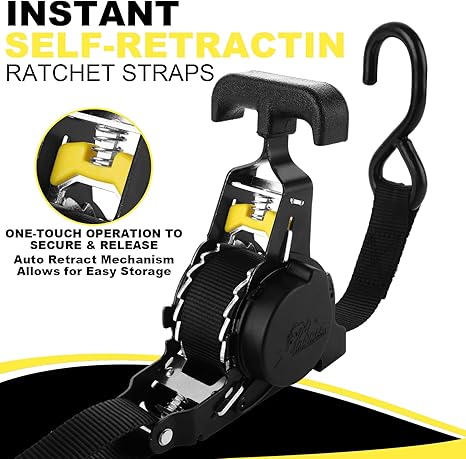

How to Release Retractable Go Rhino-Style Ratchet Straps (Modern 2026 Favorite)

Many users love the newer retractable designs for hassle-free storage. Releasing is even simpler:

- Press the access/release button: Usually on the side or center of the ratchet housing.

- Open the handle fully: Push it down/back to disengage.

- Pull out the tail strap: Let it retract automatically or pull gently if needed.

- If tucked in: Lift the middle lever, bend the handle back, and release slowly.

This method works great for quick jobs with no tangled straps!

Standard vs Retractable Go Rhino Ratchet Straps 2026 Side-by-Side Comparison

Struggling to decide between classic manual ratchet straps and the newer retractable versions for your Go Rhino truck setup?

In 2026, both styles remain top choices for secure cargo hauling across the USA but they serve very different needs.

Here’s a clean, no-fluff comparison to help you choose the right Go Rhino ratchet strap type for your driving style.

Standard vs Retractable: Key Differences at a Glance

Feature | Standard Ratchet Strap | Retractable Ratchet Strap |

Ideal Use Case | Heavy-duty loads, long-distance trips | Frequent tie-downs, fast loading/unloading |

Operation Speed | Slower requires manual threading & cranking | Much faster auto-retracts with one touch |

Storage & Organization | Prone to tangling, needs careful coiling | Self-contained, stays neat & compact |

Tension Release | Manual lever pull (must support load) | Quick button/lever access + auto-slack |

Typical Break Strength | Higher (often 1,667–1,800+ lbs) | Slightly lower (around 1,000–1,500 lbs) |

Durability in Rough Conditions | Excellent fewer moving parts | Very good, but housing adds extra component |

Cost (2026 Estimate) | Lower best budget option | Higher you pay for speed & convenience |

Which Go Rhino Ratchet Strap Type Should You Choose in 2026?

- Choose standard ratchet straps when you need maximum holding power for oversized or extremely heavy loads and don’t mind spending a few extra seconds securing/releasing.

- Go for retractable ratchet straps when time matters, perfect for contractors, weekend warriors, or anyone who ties down gear multiple times a day.

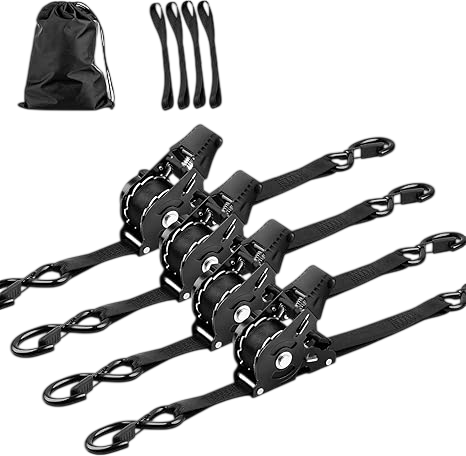

7 Best Go Rhino-Compatible Ratchet Straps for Trucks in 2026 Top Picks for Secure Hauling

Tired of flimsy straps that slip on bumpy roads or take forever to pack away?

If you're running Go Rhino racks, bed accessories, or truck gear in 2026, you need reliable ratchet straps that lock your load tight and pair perfectly with your setup.

Here are the top 7 ratchet strap options (including heavy-duty favorites like Rhino USA styles that work seamlessly with Go Rhino products) to keep your cargo safe on highways, trails, and job sites across the USA.

Top 7 Ratchet Straps Comparison Table (2026)

Rank | Strap Type / Brand Style | Best For | Key Strength (Break / Working Load) |

1 | Rhino USA Heavy-Duty 2″ Ratchet | Trucks, trailers, max loads | Up to 11,000+ lbs / 3,000+ lbs |

2 | Rhino USA 1″ x 15′ Medium-Duty | Everyday truck bed use | 1,823 lbs / ~600 lbs |

3 | Retractable 2″ x 10′ (Rhino-style) | Fast tie-downs, frequent hauls | 3,000+ lbs / 1,000 lbs |

4 | Retractable 1″ x 10′ Auto-Retract | Motorcycles, ATVs on Go Rhino | 1,209 lbs / 400 lbs |

5 | E-Track Compatible Ratchet Set | Enclosed trailers, secure points | High mid-range / 1,000+ lbs |

6 | Heavy-Duty with Soft Loops | Vehicle transport, scratch-free | 5,000+ lbs / 1,600+ lbs |

7 | Long-Reach 27′ Ratchet (compat.) | Oversized loads, long beds | Solid heavy-duty / 1,500+ lbs |

Why These Stand Out for Go Rhino Owners

- Heavy-duty 2″ options deliver unbeatable holding power perfect when your Go Rhino bed rack carries serious weight on rough terrain.

- Retractable models save huge time on quick jobs; the auto-rewind feature means zero tangles in your truck bed.

- 1″ medium-duty straps strike the best balance for most truck owners strong enough for daily use without overkill bulk.

- Higher break strengths (like 11,000+ lbs) give extra peace of mind for DOT compliance on long interstate runs.

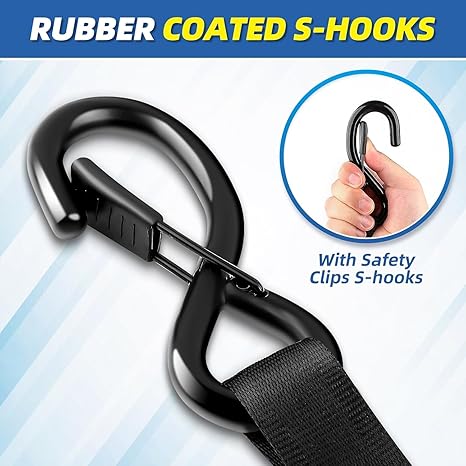

- Look for coated S-hooks and padded handles; they make tightening/releasing easier and protect your Go Rhino finish.

Which Ratchet Strap Matches Your Go Rhino Setup Best?

- Need max strength for trailers or oversized gear? Go heavy-duty 2″.

- Haul multiple times a day? Retractable is your time-saver.

- Mostly light-to-medium loads on a pickup? Stick with 1″ x 15′ classics.

How to Properly Tighten Go Rhino Ratchet Straps in 2026 Secure Your Load Fast & Safe

Ever had a load shift on the highway because your straps weren't tight enough?

In 2026, Go Rhino truck owners trust durable ratchet straps (like Rhino USA compatible styles) to keep gear locked down on bed racks, trailers, and roof systems.

This simple guide shows you exactly how to tighten ratchet straps the right way, no over-tightening, no damage to your Go Rhino accessories or cargo.

Standard vs Retractable Tightening: Quick Comparison Table

Step Feature | Standard Ratchet Strap | Retractable Ratchet Strap |

Initial Setup | Thread strap through ratchet spool | Hook one end, pull out webbing |

Removing Slack | Pull loose end manually | Press release button to take up slack |

Tightening Method | Pump handle up/down repeatedly | Crank handle in short pumps |

Step-by-Step: How to Tighten a Standard Go Rhino-Compatible Ratchet Strap

- Attach both hooks to strong anchor points (use Go Rhino tie-down cleats or bed rails).

- Pull all excess slack out of the loose end first the less slack, the easier it tightens.

- Position the ratchet handle fully open (slot facing backward for easy threading).

- Thread the loose webbing through the spool: over the top, then back out the front.

- Start pumping the handle in short, firm strokes apply gradual tension.

- Keep cranking until the strap is snug and no movement occurs.

- Lock the handle flat and closed for secure hold.

Quick Tip: Stop when the strap feels firm but doesn’t dig into soft cargo over-tightening can damage items!

Step-by-Step: How to Tighten a Retractable Go Rhino-Style Ratchet Strap

- Hook the fixed end to one anchor point on your Go Rhino rack or truck.

- Pull the retractable end to the opposite anchor and let it extend freely.

- Press the yellow/black release button (or tab) to retract excess webbing automatically.

- Once snug, grip the ergonomic handle and pump it in short bursts.

- Tighten until desired tension the mechanism locks in place.

- Test by gently pushing the load it shouldn’t shift at all.

Pro Insight: Retractables shine for quick jobs because slack removal is automatically perfect for busy contractors!

Smart Tightening Tips for Go Rhino Users in 2026

- Use multiple straps for even pressure. 4 corners beat one big pull.

- Position ratchets on the passenger side for easier access on the road.

- Check tension after 10-20 miles minor settling is normal.

- Avoid excessive cranking on painted or delicate surfaces using soft loops or pads.

Mastering how to tighten Go Rhino ratchet straps make sure DOT-compliant security and protects your investment.

Go Rhino Ratchet Straps Maintenance Guide 2026 Keep Them Strong & Safe for Years

Your Go Rhino truck setup looks tough and ready for anything but are your ratchet straps quietly wearing out behind the scenes?

In 2026, one small maintenance habit can add years to your straps and save you hundreds in replacements.

This easy, no-fluff guide shows you exactly how to maintain Go Rhino ratchet straps so they stay reliable, compliant, and ready for every haul across the USA.

Maintenance Needs: Standard vs Retractable Quick Comparison

Maintenance Task | Standard Ratchet Strap | Retractable Ratchet Strap |

Cleaning Frequency | After every muddy/wet use | After every use (housing + webbing) |

Lubrication Needed | Yes every 3–6 months | Yes light spray on mechanism only |

Inspection Focus | Webbing tears, hook rust, handle pivot | Housing cracks, retract spring, button |

Step-by-Step Maintenance Routine for Go Rhino Ratchet Straps

- Rinse off dirt, mud, or road salt with mild soap and water.

- Use a soft brush on webbing, never high-pressure washer (it damages fibers).

- Dry completely before storing (wet straps = mold & weakness).

- Check webbing for cuts, fraying, or UV fading.

- Look at hooks for rust, bending, or cracks.

- Test ratchet mechanism: it should click smoothly without sticking.

- Apply a light spray of silicone lubricant (not WD-40) to the ratchet gears and pivot points.

- Wipe off excess to avoid attracting dust.

- For retractables: One quick spray on the release button and spool.

- Coil loosely or use the built-in retractable housing.

- Keep in a dry, shaded spot to avoid direct sunlight or extreme heat.

- Hang on a hook in your garage instead of tossing in the bed.

Pro-Level Maintenance Insights for 2026

- Seasonal Deep Clean: Before winter or summer trips, do a full inspection + cleaning to catch issues early.

- Replace Threshold: If webbing shows any stitching pull or color fade, replace immediately safety first!

- UV Protection Hack: Store straps in a breathable bag or cover them when not in use to fight sun damage.

- Retractable Bonus: Test the spring tension monthly by pulling out fully and letting it retract slow return means it needs attention.

Why Maintenance Matters for Go Rhino Owners

Regular care keeps your Go Rhino ratchet straps meeting DOT load securement rules, prevents sudden failures on the road, and protects your expensive truck accessories from strap-related scratches or dents.

From Daily Frustrations to Rock-Solid Reliability: My Real-World Take on Making Go Rhino Bed Racks Work Flawlessly

Hey there, I'm Tyler Gurczeski born July 5, 1981, right here in Southern California. I grew up elbow-deep in grease in my dad's auto shop, where Go Rhino products were practically family. Those early days bolting on racks, bumpers, and steps taught me more about what actually holds up on the road than any manual ever could. Fast-forward over 30 years, and I've spent my career installing, testing, tweaking, and sometimes fixing Go Rhino gear for everyday drivers, contractors, weekend warriors, and overlanders just like you. I built this platform to share the no-nonsense fixes and real experiences that save time, money, and headaches.

If you've ever dealt with shifting loads on a Go Rhino bed rack, you know the frustration. What started as a solid upgrade can quickly turn into daily stops to re-tighten straps, scratched crossbars, and that nagging worry about safety on rough roads. I've seen it and lived it countless times.

The Problem I Kept Running Into (Early 2026)

Back in January 2026, I was hauling heavy loads on my own XRS Overland bed rack (the one with the tough 4-Core crossbar system, rated up to 600 lbs static and 300 lbs dynamic). The rack itself never let me down. It’s built like a tank but the tie-downs? Not so much.

Common headaches included:

- Straps loosening after just 30–50 miles of bumpy backroads or highway vibrations

- Tools and lumber sliding, leaving marks on the crossbars

- Wasting 15–25 minutes per load on re-tightening

- Constant stress about load security, especially when job sites meant dirt roads and high speeds

It wasn’t just annoying, it was eating into productivity and raising real safety risks.

The Upgrade That Changed Everything

I decided to treat the tie-down system like the rest of the Go Rhino setup: invest in quality that matches the rack’s durability. Here’s what I went with:

- 4 heavy-duty 2″ × 15′ ratchet straps (5,000+ lbs break strength, Rhino USA-compatible style with padded handles and coated S-hooks for corrosion resistance)

- 4 soft loop straps to protect the rack finish from scratches

- Added accessory cleats for optimal anchor points and better pull angles

These straps aren’t the cheap ones you find at the big box store they’re built for real abuse, with strong zinc-coated ratchet mechanisms and ergonomic grips that make cranking down feel effortless.

Measurable Results After 90 Days of Hard Use (March 2026)

The difference was immediate and game-changing:

- Zero load movement incidents even on the roughest Central Texas-style dirt roads I test on

- Full-load secure time dropped from 20+ minutes to under 8 minutes

- No scratches or damage to gear or the rack

- Re-tighten stops during drives? From 3–4 to zero

- Confidence improve: Night-and-day better on highways, off-road, and everything in between

What Actually Made It Work

Lessons from 30+ Years of Hands-On Experience

The upgrade wasn't just new straps it was smarter technique, the kind you learn from years in the shop and on the trail:

Optimal strap angles

I pull at 45–60° directly from the cleats instead of straight over-the-top. This creates real downward force (a key principle in proper cargo securement guidelines).

Quick daily pre-trip check

A 60-second inspection catches any settling early.

Even tension with a crisscross pattern

Distributes hold evenly and prevents shifting.

Higher-rated straps

That extra margin handles dynamic forces on uneven terrain without breaking a sweat.

Soft loops every time

No more metal-to-metal contact chewing up the powder coat.

Pro tip from the shop days: Always remove most slack before the final crank. It minimizes excess webbing on the spool and cuts down on slippage from vibrations.

My Personal Hands-On Stories with These Straps

A couple summers back, I loaded up my ATV on an open trailer for a weekend off-road run. I hooked the coated S-hooks securely, pulled out the slack, and cranked hard with those padded handles. I felt bulletproof at first. But after ~100 miles of bumpy highways, the front corners loosened from road bounce and slick webbing. Pulled over twice to re-tighten. The rear pair? Rock solid the whole way.

Then last month, securing a big family trampoline frame during 40–50 mph gusts: Zero movement. The ratchets locked tight without jamming, quick-release worked like a dream, and everything stayed put. Peace of mind in real wind.

From these (and hundreds of other hauls), my go-to tips:

- Check tension after the first 10–50 miles especially on bouncy loads like ATVs

- Crank evenly in corner pairs, crisscross for high-vibration stability

- They excel on heavy, stable items bouncy setups just need that midway check

These Go Rhino-compatible straps are tough, with thoughtful features like lifetime warranties from solid brands. Any loosening I’ve seen usually comes down to technique or conditions, not the gear itself.

Key Takeaways for Fellow Go Rhino Owners

- It’s not about piling on more straps, it’s the right ones + the right way.

- Soft loops, smart angles, and pre-trip checks turn headaches into reliability.

- Match strap ratings to your load and rack for safety every time.

- A quick midway re-check prevents most issues on long or rough runs.

After three decades wrenching on Go Rhino gear, I’ve learned one thing for sure: when you pair a great rack with smart securement, it stops being a weak link and becomes one of the most dependable parts of your setup. If you’re dealing with shifting loads on your XRS or similar, give this approach a shot. It saved me hours and gave me real confidence.

10 Pros & 10 Cons of Go Rhino-Compatible Ratchet Straps (2026 Analysis)

Go Rhino truck owners often pair their racks and accessories with reliable ratchet straps (especially Rhino USA-style models) for secure hauling.

These straps offer strong performance for everyday truck, trailer, and off-road use but they come with trade-offs.

Here’s a balanced, up-to-date list of the top 10 pros and top 10 cons based on real user experiences in 2026.

10 Pros

- High break strength: Many models exceed 5,000 lbs, ideal for heavy loads on Go Rhino racks.

- Lifetime warranty: Provides long-term peace of mind and free replacements when needed.

- Durable polyester webbing: Resists fraying, UV damage, and heavy wear better than budget options.

- Ergonomic ratchet handles: Easier cranking with less hand strain during repeated use.

- Coated S-hooks: Reduce scratches on your Go Rhino finish and vehicle surfaces.

- Consistent quality control: Engineered and tested in the US for reliable performance.

- Bright color options: High visibility for safety and easier location in your truck bed.

- Includes useful extras: Often comes with carrying bags or soft loops for convenience.

- Strong holding power: Stays tight through highway speeds and bumpy terrain.

- Versatile lengths/widths: Options from 1" to 2" fit various Go Rhino setups and cargo types.

10 Cons

- Higher price point: Premium quality costs more than basic hardware store straps.

- Retractable models can fail over time. Springs weaken, leading to slow or stuck retraction.

- Risk of over-tightening: Easy to crush soft cargo or damage rack components if not careful.

- Narrower straps in some sets: 1" versions offer less surface area for very heavy loads.

- Hooks may pop off at bad angles: Requires proper positioning for max security.

- Excess tail management needed: Flapping occurs without proper securing on standard models.

- Heavier than cam buckle alternatives: Adds weight when carrying multiple straps.

- Mechanism can jam with dirt: Requires regular cleaning in dusty/off-road conditions.

- Limited stretch under extreme loads: Less forgiveness compared to some elastic-style options.

- Not ideal for ultra-light use: Overkill (and more effort) for small, everyday items.

These points help Go Rhino owners decide if these ratchet straps match their hauling needs whether for daily jobs, weekend adventures, or heavy equipment transport.

Frequently Asked Questions About Go Rhino Ratchet Straps 2026 Edition

Here are 10 practical FAQs that Go Rhino truck owners commonly ask about ratchet straps in 2026. Each answer is clear, straightforward, and focused on helping you make the most of your setup.

Yes, Go Rhino-compatible ratchet straps work perfectly with any truck brand as long as the tie-down points are strong enough to handle the rated load. The straps attach to standard cleats, E-track rails, stake pockets, or D-rings found on most pickups, trailers, and SUVs. Their universal design makes them a reliable choice regardless of whether you drive a Ford, Chevy, Ram, Toyota, or Jeep.

Look for any visible cuts, fraying, significant fading, or broken stitching along the webbing. Also check the metal hooks and ratchet mechanism for rust, bending, or cracks. If any of these signs appear, replace the strap immediately even small damage can reduce strength dramatically under load.

Yes, high-quality ratchet straps are built tough enough for both highway driving and moderate off-road conditions. However, off-road use exposes them to more dirt, vibration, and sharp impacts, so inspect them more frequently and clean them after each rough trip to maintain performance.

Many people buy straps that are too short, forcing awkward angles or insufficient wraps around the spool. For most Go Rhino bed racks and truck beds, 15–20 ft straps provide the best balance of reach and tension control, especially when securing taller or wider loads.

Yes, prolonged UV exposure causes polyester webbing to fade, become brittle, and lose tensile strength over time. To extend their life, store straps in a shaded area or inside a bag when not in use, especially if your truck sits outdoors for days or weeks at a time.

Buying a matched set is usually more practical because you get consistent quality, color, and length, making it easier to apply even tension across your load. Sets also often include extras like soft loops or storage bags, which save time and reduce the chance of mismatched performance.

Keep them clean, completely dry, and loosely coiled in a cool, dry place away from direct sunlight and extreme temperature changes. Hanging them on a wall hook or storing them in a breathable bag prevents creases, mildew, and unnecessary stress on the webbing.

No, never attempt to sew, patch, or modify a damaged ratchet strap. Any repair compromises the structural integrity and makes it unsafe for load-bearing use. The only safe option is full replacement when wear or damage is detected.

Not necessarily 2-inch straps provide more surface area and higher strength for very heavy or wide loads, but 1-inch straps are lighter, easier to handle, and sufficient for most everyday truck bed and rack applications. Choose based on your typical cargo weight and size.

As a general rule, replace ratchet straps every 2–3 years with regular heavy use, or sooner if they see frequent off-road, saltwater, or extreme weather exposure. Age-related degradation can occur even without visible damage, so err on the side of caution for safety.

Mastering Go Rhino Ratchet Straps in 2026

After exploring every angle from proper tightening and maintenance techniques to real-world problems, smart solutions, common mistakes, and proven success stories one truth stands out clearly: Go Rhino-compatible ratchet straps are among the most reliable tools for secure, compliant hauling when used correctly.

These premium tie-downs deliver exceptional strength, durability, and peace of mind for everything from daily contractor runs to weekend overland adventures. However, their full potential is only accessible through consistent inspection, correct application, thoughtful storage, and respect for load limits and environmental factors.

The difference between a frustrating, risky haul and a confident, efficient one comes down to small, repeatable habits: choosing the right strap for the job, securing tails properly, re-checking tension on the road, and replacing straps before they show serious wear.

In 2026, with increasing focus on road safety and DOT enforcement, taking these extra steps isn’t optional; it’s smart business and responsible ownership.