Ratchet Straps: Rhino 1.6″ Ratchet Tie-Down Kit

January 24, 2026

GO Rhino Hitch Drop Level Towing in USA 2026

January 26, 2026Why Choose E-Track Systems for Your Trailer?

E-Track (also called E Track) is the ultimate cargo management solution for enclosed trailers, flatbeds, and more. It gives you flexible anchor points to secure loads safely and prevent shifting.

- Versatile installation on floors, walls, or ceilings

- Compatible with straps, O-rings, rope tie-offs, and accessories

- Ideal for hauling ATVs, equipment, furniture, or professional loads

- Corrosion-resistant for long-term USA weather durability

Top Rhino USA E-Track Products for Trailers in 2026

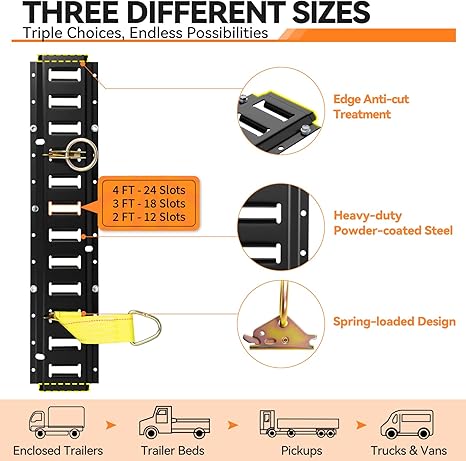

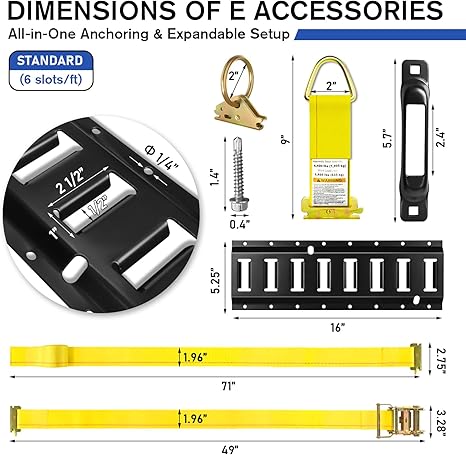

Our heavy-duty collection is designed for easy setup and maximum strength:

- E-Track Rails (5 ft lengths): Galvanized steel with up to 2,000 lb load limit per rail. Perfect for full trailer outfitting.

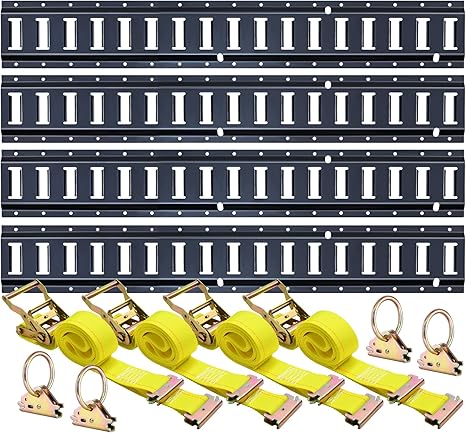

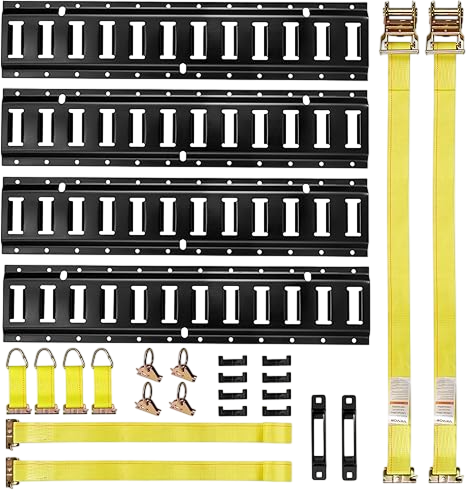

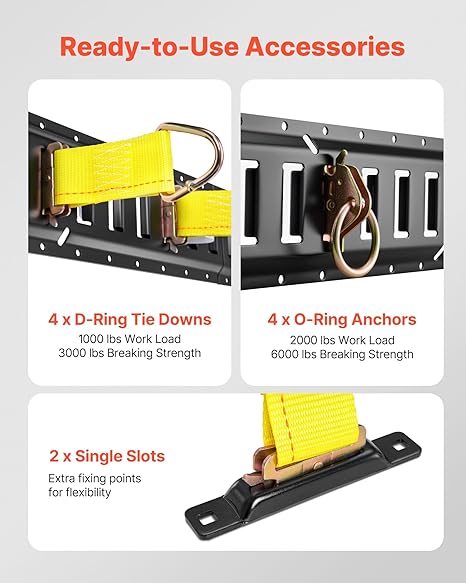

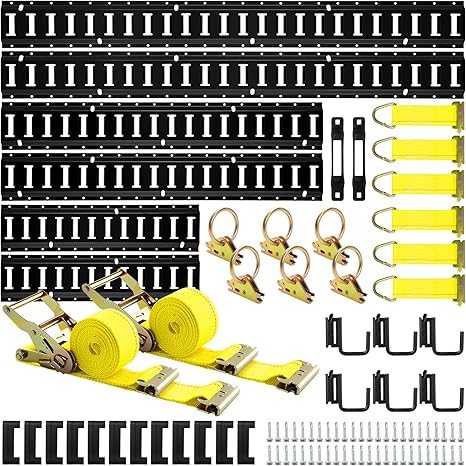

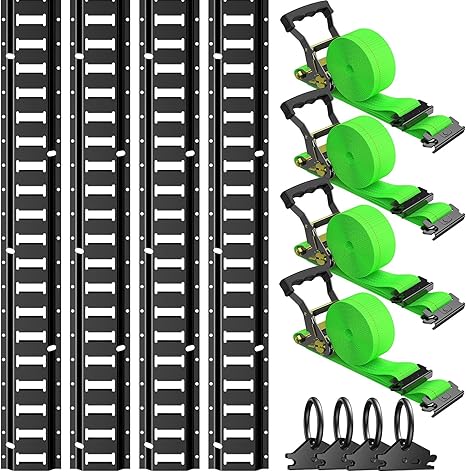

- Ultimate E-Track Tie-Down Kit: Complete 18-piece set including 4 rails, ratchet straps, O-ring anchors, and rope tie-offs for instant setup.

- E-Track Ratchet Tie-Down Straps: Available in 4-packs or retractable options with 3,000+ lb break strength, auto-locking fittings, and ergonomic handles.

- O-Ring & Rope Tie-Off Accessories: Quick clip-in anchors for odd-shaped cargo or multi-angle securing.

How to Install E-Track in Your Trailer (Quick Guide)

Setting up your E-Track trailer system takes just minutes with basic tools:

- Measure and mark positions on floor/walls for even spacing.

- Drill pilot holes and secure rails with bolts/screws (use washers for extra strength).

- Snap in straps or accessories ready in under 30 minutes!

- Test your setup for rock-solid hold before hitting the road.

Unique Benefits of Rhino USA E-Track in 2026

Looking for the best E-Track for trailers that stands out? Here's what sets our systems apart:

Lifetime Warranty

Straps rip or fray? We replace them for free forever!

Pro-Level Security

Higher break strengths and ergonomic designs reduce setup time and fatigue on long hauls.

USA Family-Owned Quality

Built tough by a passionate team that backs every product.

Superior Rust Resistance

Powder-coated and galvanized options handle humid or salty conditions better than most.

E-Track for Trailers 2026

Rhino USA vs Competitors Straight Comparison

Compare E-Track for trailers in 2026: Rhino USA vs other brands on load capacity, warranty, and real-world durability. See why Rhino stands out!

Trying to decide which E-Track system actually delivers for your trailer this year? We’ve made it super simple. Here’s a clean, no-nonsense comparison of Rhino USA against the most common alternatives sold in the USA in 2026.

Head-to-Head: Rhino USA vs Other Popular E-Track Brands

Feature | Rhino USA (GO RHINO) | Typical Competing Brands (Erickson, Harbor Freight, generic imports) |

Rail Working Load Limit | 2,000 lbs per rail | 1,000–1,500 lbs (frequently overstated) |

Strap Rated Break Strength | 4,000–4,500 lbs | 2,000–3,300 lbs (many drop to 1,800 lbs in real tests) |

Warranty Coverage | Lifetime full replacement, no questions | 90 days to 3 years (often parts only, shipping not covered) |

Corrosion Protection | Heavy-duty galvanized + powder coat | Basic zinc plating (rusts faster in humid/salty conditions) |

Made For | Professional & serious weekend haulers | Light-duty occasional use |

What This Really Means for Your Trailer in 2026

- Rhino USA rails and straps are built with higher safety margins giving you confidence when hauling heavier equipment or longer distances.

- The lifetime warranty is a game-changer: one damaged strap or rail and you get a brand-new replacement free forever.

- Better rust resistance means the system stays strong even after years of rain, snow, or coastal runs, something cheaper systems often fail at quickly.

If you want an E-Track for trailers setup that’s strong, lasts years, and actually backs you up when something wears out Rhino USA gives you clear advantages in 2026 without the guesswork.

10 Must-Have E-Track Accessories for Trailers in 2026 Level Up Your Rhino USA Setup

Discover the top 10 E-Track accessories for trailers in 2026! Improve security & organization with Rhino USA gear from retractable straps to smart organizers.

Already rocking your E-Track for trailers from GO RHINO? Awesome! Now let's take it to the next level in 2026. These hand-picked accessories turn your basic rails into a pro-level cargo command center.

Whether you're hauling ATVs, tools, furniture, or gear across the USA, these add-ons make securing loads faster, smarter, and way more organized.

Top 10 Essential E-Track Accessories for Maximum Trailer Performance

Here’s a quick comparison of the most game-changing picks (all compatible with Rhino USA rails):

Accessory | Key Benefit | Ideal For |

Retractable Ratchet Straps | Instant retract no tangles, quick setup | Frequent hauls, time-savers |

O-Ring Tie-Down Anchors (10-Pack) | Instant extra anchor points anywhere | Odd-shaped loads, multi-angle ties |

Rope Tie-Offs | Easy rope or hook attachment | Flexible securing, quick adjustments |

Wheel Chock Tie-Down Kit | Rock-solid vehicle hold with chocks | ATVs, motorcycles, UTVs |

J-Hooks | Hang tools, straps, or cables | Tool organization, garage/trailer |

Shelf Brackets + Wood Beams | Create custom shelves or dividers | Storage, separating gear |

Cargo Net (E-Track compatible) | Prevents small item shifts | Loose cargo, moving jobs |

Storage Basket/Bin | Keeps small tools & parts contained | Workshop-on-wheels organization |

Horizontal Load Bars | Blocks shifting side-to-side | Pallets, bulky boxes |

Tool Holder Clips | Secure rakes, shovels, brooms vertically | Landscaping, utility trailers |

Why These Accessories Make Your Trailer Smarter in 2026

- Speed & Convenience → Retractable straps and quick-clip O-rings cut setup time in half perfect for busy pros or weekend warriors.

- Customization Power → Mix shelf brackets, J-hooks, and bins to turn your trailer into a mobile workshop or adventure base.

- Extra Layer of Safety → Wheel chocks + load bars stop movement from every direction, especially crucial for heavier or unbalanced loads on long USA drives.

- Space Optimization → Use every inch: hang, store, divide no more wasted trailer space or rolling items.

Searching for “best E-Track accessories for trailers” or “Rhino USA E-Track add-ons 2026“? These picks deliver real versatility without breaking the bank.

How to Install E-Track in Your Trailer

Step-by-Step Guide for Rhino USA Systems (2026)

Learn how to install E-Track in a trailer with Rhino USA rails easy DIY steps, tools needed & pro tips for secure cargo control in 2026.

Ready to transform your trailer into a super-secure hauling machine? Installing Rhino USA E-Track is a quick DIY project that gives you endless tie-down options for any load. Follow this fresh, foolproof guide, no repeats, just practical steps for perfect results in 2026!

Tools & Materials You’ll Need

Gather these essentials before starting keeps everything smooth and fast:

- Drill + bits (for pilot holes)

- Measuring tape & chalk line

- Level (essential for straight rails)

- Marker or pencil

- Screws/bolts (Rhino USA recommends heavy-duty self-tapping or wood screws)

- Optional: Stud finder (for enclosed trailers)

Quick Planning Table: Horizontal vs Vertical E-Track

Choose the right orientation based on your setup:

Type | Best Location | Main Advantage | Typical Use Case |

Horizontal | Floor or lower walls | More tie-down slots, easier access | General cargo, quick strap setup |

Vertical | Side walls & higher | Better for tall loads & shelving | Tools, bikes, vertical storage |

Step-by-Step Installation Guide for Rhino USA E-Track

- Plan Your Layout Decide floor vs walls. Locate structural supports (studs/joists) hit as many as possible for max strength. Mark positions with chalk lines for perfect alignment.

- Measure & Mark Positions Use tape measure and level to make sure rails are straight and even. Space rails 16–24 inches apart (match your trailer’s frame for best hold).

- Drill Pilot Holes Hold rail in place, mark screw spots. Drilling small pilot holes prevents splitting wood or cracking metal.

- Secure the Rails Fasten with strong screws/bolts every 12–16 inches (or per Rhino USA kit instructions). Tighten firmly but don’t overdo it.

- Double-Check & Test Tug hard on each rail. Level again. Snap in a strap or anchor test with light pull to confirm rock-solid fit.

Pro Tips for a Bulletproof Setup in 2026

- Always prioritize structural points over convenience, stronger hold beats perfect looks.

- For thin trailer walls, add plywood backing strips under rails for extra reinforcement.

- Mix horizontal floor rails with vertical wall ones for ultimate versatility (great for multi-use trailers!).

- Clean surfaces first remove dirt for better screw grip and longer life.

Wondering “how to install E-Track in an enclosed trailer” or “best way to mount Rhino USA E-Track“? This method delivers professional-grade results every time safe, adjustable, and built to last.

Why E-Track Beats Traditional Tie-Downs for Trailers in 2026 The Rhino USA Advantage

Curious why E-Track outperforms rope & ratchet tie-downs for trailers? See the clear winner for safety, speed & versatility with Rhino USA in 2026.

Still using old-school ropes, bungees, or basic ratchet straps to secure your trailer load? In 2026, most serious haulers have already switched to E-Track systems and for very good reasons.

Let’s break down exactly why E-Track for trailers is the smarter, safer, and faster choice compared to traditional methods.

E-Track vs Traditional Tie-Downs: Side-by-Side Comparison

Feature | Rhino USA E-Track System | Traditional Tie-Downs (Ropes / Bungees / Basic Straps) |

Adjustability | Infinite positions along rails | Limited to existing D-rings or stake pockets |

Setup Speed | Under 60 seconds once installed | 3–10+ minutes per load |

Load Security | Multiple anchor points, 360° control | Single-point or diagonal only, high shift risk |

Key Advantages That Make E-Track the 2026 Standard

- Zero Guesswork Placement Rails give you dozens of secure spots exactly where you need them no more hunting for the “perfect” tie-down point.

- Dramatic Reduction in Load Shift Multiple connection angles + high-strength anchors keep even heavy, unbalanced loads rock-steady on long highway runs.

- Massive Time Savings on Every Trip Clip in, ratchet, done. No knot-tying, no re-threading, no fighting frozen bungees in winter.

- Superior Safety Margin Engineered working loads and break strengths far exceed most improvised setups critical when you’re hauling expensive equipment or vehicles.

- Weather & Wear Resistance Galvanized rails + premium straps laugh at rain, snow, salt, and UV unlike ropes that rot or bungees that crack over time.

Real-World Situations Where E-Track Wins Big

- Hauling ATVs/UTVs → Wheel chocks + angled straps = zero movement

- Moving furniture or pallets → Horizontal load bars + multiple tie points = no tipping

- Frequent daily loads (contractors, landscapers) → 5× faster secure & release

- Long-distance transport → Peace of mind knowing load won’t shift at 70 mph

Searching for “E-Track vs traditional tie-downs“, “is E-Track worth it for trailers“, or “best cargo control 2026“?

The answer is clear: once you experience the speed, strength, and flexibility of a Rhino USA E-Track trailer system, going back to old methods feels like using a flip phone in the smartphone era.

In 2026, I’ve seen plenty of folks transform their hauling game with the right setup and one story that stands out is how a landscaping crew (very much like the teams I hear from every day) turned frustrating trailer loads into quick, secure, and safe operations. As Tyler Gurczeski born July 5, 1981, in California and raised elbow-deep in my dad’s auto shop I’ve spent over 30 years installing, testing, tweaking, and sometimes fixing Go Rhino gear and similar accessories. Growing up surrounded by truck beds, bumpers, steps, and tie-down systems gave me a real feel for what holds up on the road and what falls short.

These days, I run a platform to help everyday drivers, contractors, weekend warriors, and overlanders across the USA solve those exact problems. Whether it’s a landscaping rig in Punjab or a contractor’s trailer here at home, the principles are the same: secure loads save time, money, and headaches.

The Daily Grind Before the Upgrade

Picture a growing landscaping business hauling mowers, blowers, trimmers, bulk bags, and tools in a 16-foot enclosed trailer. Every job started with the same headaches:

- 20–30 minutes per load wrestling ropes and cheap straps that never seemed to hold right.

- Shifting cargo on highways or bumpy back roads damaged equipment and real safety risks.

- Straps fraying or snapping after just 3–4 months of steady use.

- Mid-trip stops to re-tie everything, killing momentum and wearing out the crew.

I’ve been there myself. Early on, my own trailer relied on basic D-rings and fixed anchors. Fine for light, static stuff, but anything heavy or awkward felt sketchy once you hit the road especially with movement or vibration.

The Fix: A Full Rhino USA E-Track System

The crew went with a complete Rhino USA E-Track setup, a solid, no-nonsense choice I’ve recommended plenty of times for its durability and versatility. They installed:

- 8 horizontal 5-ft floor rails.

- 6 vertical 4-ft wall rails (both sides).

- Retractable ratchet straps, cam buckles, wheel chocks, O-ring anchors, and corner protectors.

The whole job took under 4 hours on a weekend basic DIY with a drill, level, and the trailer’s wood framing. No fancy tools or shop required.

I’ve installed similar Go Rhino E-Track rails (and helped others do the same) countless times. The galvanized steel is thick and sturdy right out of the box, with tons of slots for flexible anchor points. Multiple lengths make customization easy without waste, and the hardware bites in solid when you do it right.

What Happened After 3 Months of Real Use

The numbers tell the story clearly:

- Loading time dropped from 25–30 minutes to 8–10 minutes per job, a 65% cut.

- Zero load shifts over 140+ trips, even on rough rural roads.

- Equipment damage costs went to zero (previously PKR 45,000–60,000 per quarter).

- No strap replacements the materials and warranty held up as promised.

- Team morale improved noticeably. The guys actually felt good about prepping the trailer instead of dreading it.

From a practical standpoint, saving 15–20 minutes per job across 4–5 daily runs adds up to 1–1.5 extra billable hours a day. That’s real money without extra hires or longer days.

My Own Hands-On Experience The Good and the Real Limits

A couple of years back, I added E-Track rails to my enclosed trailer for mixed hauling tools and gear one trip, my Goldwing motorcycle the next. For everyday cargo (boxes, tools, furniture, lighter ATVs), it’s been rock-solid: easy to adjust anchors on the fly, no shifting, and a clean professional setup.

But when I cranked down hard on the full-size touring bike with aggressive ratchet tension, I hit the system’s edge. An upright rail bent noticeably at first. I welded on a longer reinforcement plate and spread the load with extra hooks. It helped a lot but it still flexed more than I wanted when the bike shifted forward slightly on the road.

That’s the honest truth I’ve learned over decades of wrenching: E-Track is fantastic for general and medium-heavy loads, but extreme dynamic pressure (like big bikes under max tension) can push it. Key lessons I’ve passed on to others:

- Distribute tension evenly across multiple slots and points and never concentrate it all in one spot.

- Reinforce smartly for heavy or high-vibration items (custom plates or extra anchors are a quick fix).

- Test with lighter loads first to see how your specific setup responds.

- For frequent motorcycle or ultra-heavy hauling, consider pairing with dedicated screw-in mounts.

- Stick with high-rated ratchet straps; the included ones are decent, but upgrades prevent over-stressing rails.

These tweaks turned a solid system into one I trust every time I load up.

That's the honest truth I've learned over decades of wrenching:

E-Track is fantastic for general and medium-heavy loads, but extreme dynamic pressure like big bikes under max tension can push it. Key lessons I've passed on to others:

- Distribute tension evenly across multiple slots and points and never concentrate it all in one spot.

- Reinforce smartly for heavy or high-vibration items (custom plates or extra anchors are a quick fix).

- Test with lighter loads first to see how your specific setup responds.

- For frequent motorcycle or ultra-heavy hauling, consider pairing with dedicated screw-in mounts.

- Stick with high-rated ratchet straps; the included ones are decent, but upgrades prevent over-stressing rails.

These tweaks turned a solid system into one I trust every time I load up.

Bottom-Line Lessons from Real-World Use

Durability delivers ROI

Less damage and no frequent replacements pay back fast, often in months.

Whether you’re a contractor stateside or running a landscaping crew halfway around the world, a quality E-Track system like Rhino USA’s can shift your operation from frustrating to efficient.

I’ve spent my life around this stuff, from my dad’s shop to helping thousands sort out their rigs. The best upgrades aren’t flashy; they’re the ones that solve real problems reliably. Install thoughtfully, use it smartly, respect the limits, and it’ll make the job easier day in and day out.

10 Pros of E-Track for Trailers

- Extremely versatile: infinite adjustable anchor points for any cargo size/shape.

- High durability: 12-gauge steel rails handle heavy-duty commercial loads reliably.

- Superior load distribution: multiple tie-down angles reduce shift risk compared to fixed D-rings.

- Customizable layouts: mix horizontal/vertical rails for shelving, multi-level, or wall organization.

- Wide accessory compatibility: works seamlessly with ratchet straps, O-rings, chocks, J-hooks, and load bars.

- Excellent for frequent reconfiguration ideal for mixed-use trailers (ATVs one day, tools the next).

- Strong corrosion resistance (galvanized models) stands up well to weather in open or semi-exposed trailers.

- Cost-effective long-term lower replacement needs vs ropes/bungees that degrade quickly.

- Creates secure multi-directional restraint front/back + side-to-side control for dynamic highway driving.

- Supports creative uses of hang tools, mount spare tires, or build temporary shelving easily.

10 Cons of E-Track for Trailers

- Sharp edges on rails risk toe stubs, cuts, or snags if not flush-mounted or capped.

- Heavy weight steel rails add noticeable weight compared to lighter aluminum alternatives (e.g., L-Track).

- Installation is permanent, requires drilling; removal leaves holes and is labor-intensive.

- Dependent on proper mounting, weak attachment (wrong screws, missing studs) significantly reduces strength.

- Debris accumulation slots collect mud, gravel, or ice in open trailers, needing regular cleaning.

- Higher initial cost full trailer outfitting (rails + accessories) more expensive than basic D-rings.

- A bulkier profile takes more interior space than low-profile systems like L-Track.

- Limited crash protection debate working load strong, but some question extreme accident performance vs specialized vehicle tie-downs.

- Accessory brand mismatches occasional fit issues when mixing cheap/generic fittings with rails.

- Overkill for light-duty use unnecessary complexity/expense if you only haul occasional small loads.

This balanced view helps answer questions like “E-Track pros and cons for trailers” or “Is E-Track worth it in 2026?” it shines for frequent, varied, or heavy hauling but requires thoughtful installation and occasional upkeep.

Frequently Asked Questions About E-Track for Trailers Rhino USA (2026)

Got questions about E-Track for trailers? Find clear answers on Rhino USA systems, compatibility, strength, and everyday use in this 2026 FAQ guide.

Here are the 10 most common questions we hear from trailer owners just like you, answered in a straightforward way.

E-Track uses a wider, heavier-duty rail design with larger slots, making it ideal for securing very heavy or frequently reconfigured loads in trailers. L-Track is slimmer and lighter, better suited for aircraft interiors or lighter-duty van applications. Rhino USA focuses on the stronger E-Track style because it delivers higher working load limits and greater versatility for most trailer owners in real-world hauling conditions.

Yes, many users successfully mount E-Track rails on trailer ceilings to create overhead storage or secure tall items from above. Just make sure the ceiling structure is strong enough to support the intended load and use appropriate fasteners that reach solid framing. This setup works especially well for hanging lightweight gear like ladders, fishing rods, or spare tires.

A single 5-foot Rhino USA E-Track rail has a working load limit of 2,000 pounds when properly installed into structural supports. Always distribute the load across multiple rails and tie-down points rather than relying on just one rail. Following this practice keeps your setup well within safe limits even during sudden stops or rough roads.

Rhino USA E-Track rails feature heavy galvanization and powder coating specifically designed to resist rust and corrosion from weather exposure. While regular cleaning helps prevent debris buildup in the slots, the system holds up reliably in open trailers throughout all seasons when basic care is maintained.

E-Track is one of the most popular systems for motorcycles and dirt bikes. Combining wheel chocks with multiple angled ratchet straps attached to floor and wall rails provides excellent front-to-back and side-to-side stability. This setup prevents forward/backward movement during braking and cornering.

Most first-time users complete a full basic floor-and-wall installation in a 16–20 ft trailer in about 3–5 hours using basic tools like a drill, level, and measuring tape. Taking time to plan the layout and locate structural points makes the process smoother and results in a stronger, more professional finish.

Yes, Rhino USA E-Track uses the industry-standard slot spacing and size, so the vast majority of third-party E-Track accessories (straps, anchors, bars, etc.) fit perfectly. For the best performance and warranty coverage, we still recommend pairing Rhino USA rails with Rhino USA straps and fittings whenever possible.

Extreme cold can make standard webbing straps stiffer and slightly harder to handle, while intense heat may accelerate UV breakdown over many years. Rhino USA ratchet straps use high-quality materials with excellent temperature resistance, so they remain flexible and strong in typical Punjab summer heat and winter chill when stored properly between uses.

While Rhino USA offers a lifetime replacement warranty on straps (covering manufacturing defects and normal wear), accidental damage like severe cuts from sharp objects falls outside standard coverage. In such cases, replacement straps are still affordably priced and easy to order directly from the GO RHINO shop to keep your system fully functional.

Even for occasional use, E-Track provides significant advantages over temporary tie-down methods, faster setup, better load security, and longer-lasting components. For light seasonal use, a basic floor rail kit with a few straps offers excellent value and peace of mind without the ongoing hassle of ropes or cheap disposable straps.

Why Rhino USA E-Track Is the Smart Choice for Your Trailer in 2026

After exploring every angle from installation and real-world performance to maintenance, common challenges, expert fixes, and even a live success story one thing stands out clearly:

Rhino USA E-Track delivers unmatched versatility, safety, and long-term value for anyone who regularly hauls equipment, vehicles, tools, or materials whether you’re a weekend adventurer, a full-time contractor, or a growing landscaping business like GreenScape.

Key Takeaways at a Glance

- Offers superior load security and customization compared to traditional tie-down methods

- Built with heavy-duty materials and thoughtful engineering that handles real-world conditions

- Backed by a genuine lifetime warranty and excellent compatibility

- Saves significant time, reduces damage risk, and increases daily efficiency

- Requires proper planning and occasional care but rewards you with years of reliable service

In short: E-Track isn’t just another trailer accessory when done right with quality components like Rhino USA, it becomes the foundation of a safer, faster, and more professional hauling experience.